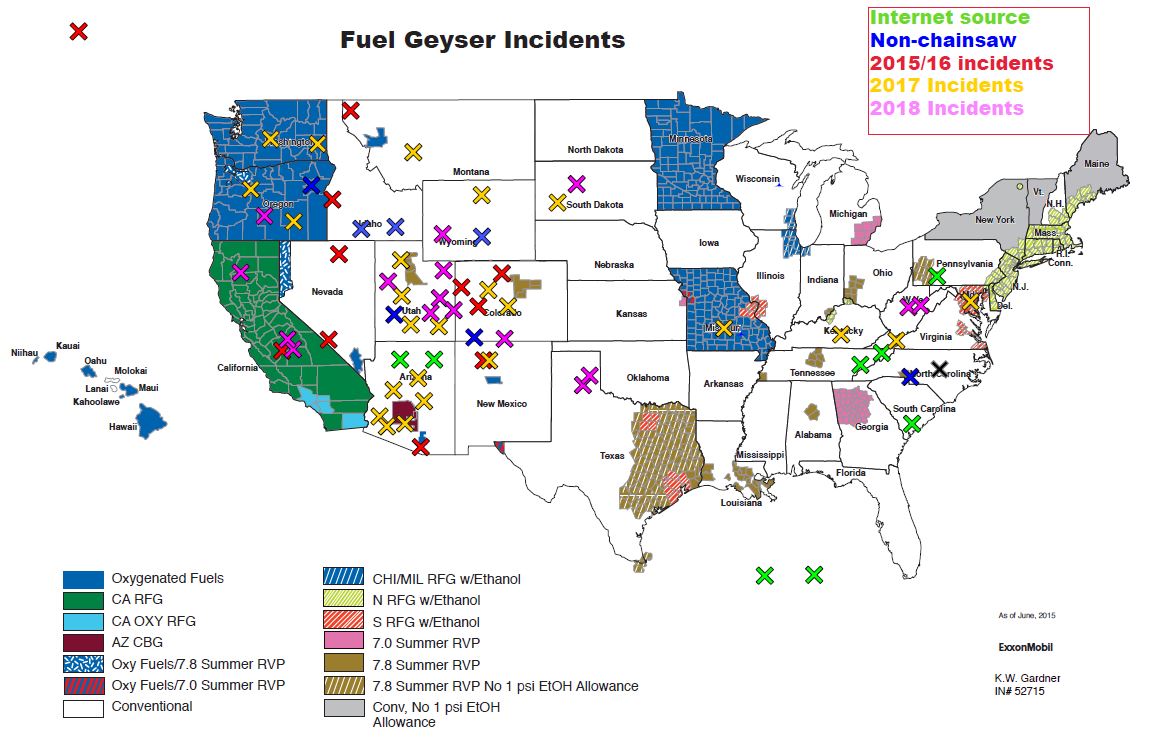

In 2018 there were 28 reports of fuel geyser incidents, in which fuel and vapor are expelled with force from a fuel tank or container. These can be dangerous, especially when ignition sources may be in close proximity, such as when a person is fighting a fire.

For years the land management agencies have been warning firefighters about the dangers of gasoline being forcefully released from chainsaws. Some of these incidents have occurred with saws that have the newer quarter-turn gas caps. After a saw has been running for a while pressure can build up in the gas tank causing vapor lock, which can prevent the saw from running. Thinking it may be out of fuel, the operator opens the quarter-turn gas cap and the pressure in the tank forces out fuel and vapor. If there is an ignition source nearby, it can quickly ignite and cause very serious injuries.

The Wildland Fire Lessons Learned Center reported that of the 28 fuel geyser incidents reported in 2018, 23 involved chainsaws (21 with Stihl saws and 2 with Husqvarnas). Four incidents occurred with fuel containers, and one occurred with a leaf blower.

Over the last half decade or so several firefighters have been seriously burned in fuel geyser incidents. We reported some of them here, here, and here.

A 2015 report by the Bureau of Land Management identified possible pressurization hazards associated with fuel systems on 12 models of chainsaws:

- Stihl 036, 044, 046, MS-361, MS-362, MS-441, MS-461, MS-660, MS-880;

- Husqvarna 340, 345, 350

The BLM and other agencies have been working to figure out why fuel geysers occur and how to prevent additional injuries. On the list of recommendations that they have developed one of the most important is to open fuel caps very slowly and cover the cap with a rag to contain potential fuel geyser spray. If it begins to geyser, close it and let the engine and tank cool for an extended period of time. And don’t open the cap at all if the tank is over half full.

Here is the complete list from the National Wildfire Coordinating Group:

- Always assume fuel tanks and fuel containers are pressurized.

- Ensure the cap is correctly secured.

- Always check fuel levels before opening the fuel tank or filler cap. Fuel levels greater than ½ tank may geyser.

- Open cap slowly and if able, direct potential spray away.

- Cover the cap with a rag to contain potential fuel geyser spray.

- Always check fuel levels before opening a fuel cap.

- Be extra vigilant when equipment is running poorly with fuel levels above ½ tank.

- Move at least 20 feet away from any heat source.

- Start the saw at least 10 feet from the fueling area.

- Do not use fuel older than one month.

If the equipment is running poorly or vapor lock is suspected:

- Do not open fuel cap. Relieving the pressure does not alleviate a “vapor lock” equipment.

- Check fuel level through the tank or use the bar oil level to gage fuel level.

- If fuel level is over ½ full, DO NOT open the tank.

- Allow the equipment to thoroughly cool. This could take over 45 minutes.

- When the equipment is cool, restart the equipment.

This video demonstrates what fuel geysering looks like. I don’t know which is worse — having it happen when you are 30-feet above the ground or near a wildfire.

The National Technology and Development Program’s National Fuel Geyser Project has proposed some possible solutions to fuel geysering, including 1) Vaporless Refueling Systems; 2) Formalized Fuel Geyser Training; 3) Standard Saw/Requirements; 4) No Gas Chainsaws; 5) Specialized Fuel; and 6) Fuel Conditioning.

In the meantime the Project hopes to continue its field evaluation of vaporless refueling systems. This would include 50 test crews and 30,000 refueling cycles from May through November of this year. This field evaluation would be implemented on all handheld-engine powered devices — chainsaws, string trimmers and blowers.

They are also working on these issues:

- Vaporless Refueling System – by Industry and the National Technology and Development Program.

- Saw Specification/Requirements – by the National Technology and Development Program.

- Training – by Saw Program/Office of Safety and Occupational Health (OSOH)

The NWCG encourages field personnel to continue to report incidents of fuel geysering. Their National Fuel Geyser Awareness page has a link to a reporting system.