This article first appeared on Fire Aviation.

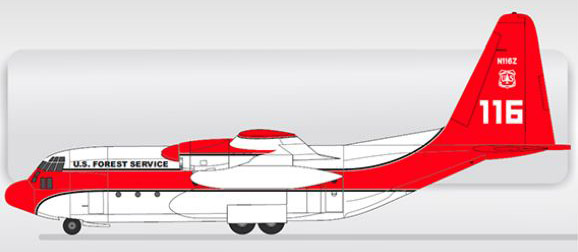

After a solicitation process that dragged on for almost two years, the U.S. Air Force has awarded the contract to build and install retardant delivery systems for up to seven of the seven HC-130H aircraft that are being transferred from the Coast Guard to the U.S. Forest Service.

The Coulson Group announced today that they received the contract. In one sense this is not unexpected because the company has installed and successfully operated two similar systems in C-130s — Tanker 131 and Tanker 132. In another sense, it is a surprise after the Government Accountability Office denied the company’s protest of the terms of the request for proposals in August of 2015.

“We are excited to have the opportunity to work with the United States Air Force to provide them with state of the art retardant aerial delivery systems (RADS) for their fleet of C-130s,” says Wayne Coulson, CEO and President of Coulson Aviation.

The 3,800-gallon retardant system will be gravity-based with retardant tanks that can be quickly removed, making it possible for the air tankers to also haul cargo or passengers.

One of the seven HC-130H aircraft began working out of McClellan Air Field near Sacramento last summer. Since it did not have a permanent retardant tank it borrowed one of the Forest Service’s eight Modular Airborne FireFighting Systems (MAFFS) that can be inserted into the cargo hold of a military C-130 to provide a surge capacity of air tankers during a time of heavy wildfire activity. The MAFFS pump the 3,000 gallons of retardant out of a pipe through the door using compressed air, rather than letting it drop out of the belly with the assistance of gravity as is done with conventional air tankers.

The Air Force is responsible for the retrofitting and performing the heavy maintenance that must be completed before the seven HC-130Hs are finally turned over to the USFS over the next three years. This contract is for the installation of one trial “kit”, one verification kit, and three production kits. There is an option for the installation of two additional production kits.

Coulson Aviation has 25 years of experience in aerial fire suppression and they operate both Type 1 helicopters and large fixed wing air tankers. Coulson is one of the few companies to hold multi-country aerial firefighting contracts, including Canada, the United States, and Australia.

Could water-scooping air tankers mix retardant in their tanks after scooping in the limited time before dropping their loads? Or even inject an air-foam mix? What are the limits for doing this?

It would be difficult to mix dry power retardant with water on board an aircraft. But several air tankers carry a tank of foam or gel concentrate that can be mixed with the water that is scooped or pumped on board. Examples: Martin Mars, 747 Supertanker, Be-200, and CL-415.

An organization in Russia has created a helicopter bucket apparatus that creates medium expansion foam, with a volume many times greater than plain water or foam concentrate that is simply injected into water and dropped, forming some bubbles as it passes through the air.

With all the modern technology available in this day and age, Why hasn’t anyone build a Waterbomber that can reload like the Mars

Glenn, if you mean scoop water while skimming over the surface of a lake, there are many air tankers that can do that, including the CL-215/415, Air Tractor Fire Boss, and Russia’s Be-200. China is currently building a large amphibious aircraft that will be able to scoop.