A federal judge ruled Friday that the U.S. government can continue using retardant to fight wildfires, despite his finding that it does pollute streams in violation of federal law. Banning retardant could cause greater environmental damage from wildland fires, said U.S. District Judge Dana Christensen in court in Missoula, Montana.

The judge agreed with U.S. Forest Service officials who testified that dropping retardant from aircraft into areas near waterways was sometimes necessary to protect lives and property, according to an AP report posted by KEZI-TV.

Christensen’s ruling resulted from yet another lawsuit filed last year by an environmentalist group trying to protect fish over people when they learned that the Forest Service had dropped retardant into waterways — what they claim was hundreds of times over the last decade.

The lawsuit is on file HERE: (PDF file).

Retardant is often crucial in slowing the progression of wildfires, which have grown larger and more destructive and more frequent as climate change and a burgeoning wildland/urban interface advance the danger of fires across the West — and other parts of the world.

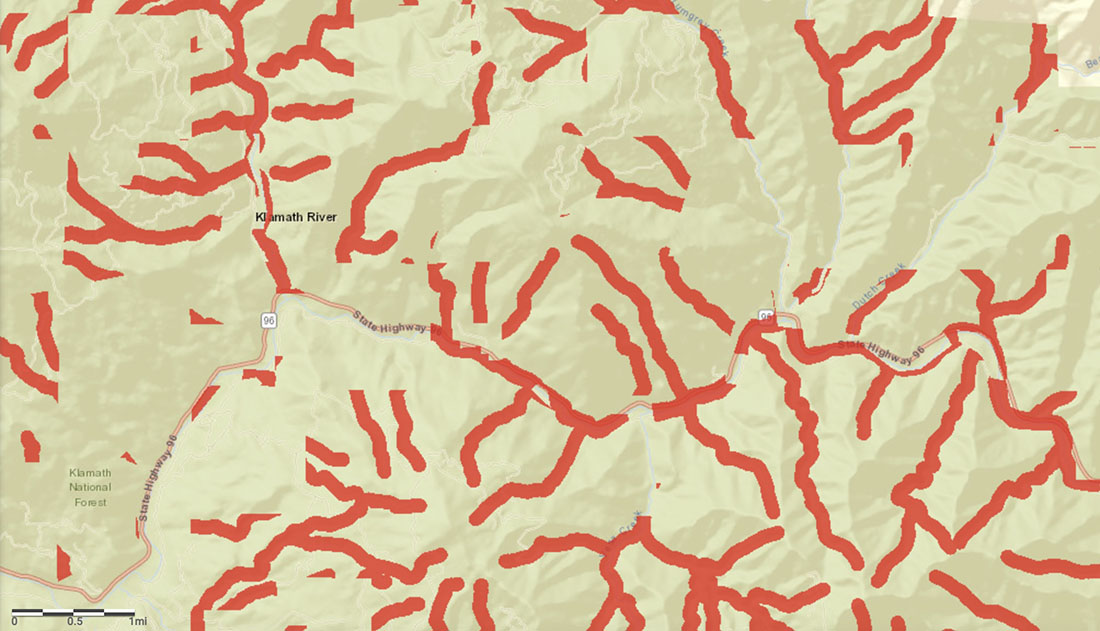

Though environmental groups claim fire suppression efforts allowed incursions of retardant more than 200 times over the last 10 years, fire officials reply that such situations happened accidentally — and in less than 1 percent of the thousands of retardant drops ordered each year.

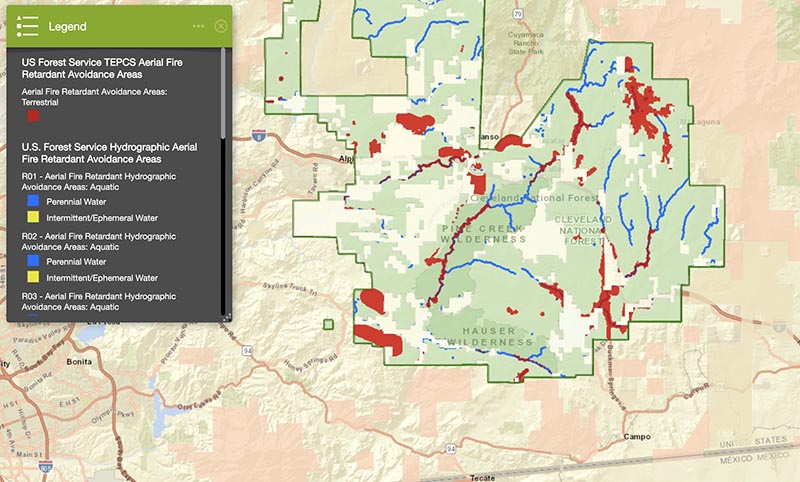

During this case — yet another in the decades-long battle by environmental groups against the use of retardant — a coalition including Paradise, California said stopping the use of retardant would risk lives, homes, and forests. (The 2018 Camp Fire killed 85 people and destroyed the town of Paradise.) There’s a good story online about this coalition by AerialFire Magazine.

“This case was very personal for us,” said Paradise Mayor Greg Bolin on Friday. “Our brave firefighters need every tool in the toolbox to protect human lives and property against wildfires, and today’s ruling ensures we have a fighting chance this fire season.”

“Retardant lasts and even works if it’s dry,” said Scott Upton, a former region chief and air attack group supervisor for CAL FIRE. “Water is only so good because it dries out. It does very well to suppress fires, but it won’t last.”

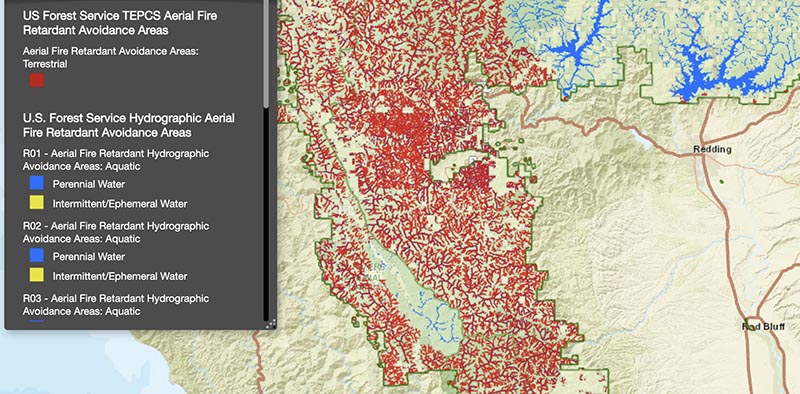

KDVR-TV reported that the Oregon-based group Forest Service Employees for Environmental Ethics (FSEEE) argued in its most recent lawsuit that the Forest Service was disregarding the Clean Water Act by continuing to use retardant without taking adequate precautions to protect streams and rivers. Launched by Jeff DeBonis in 1989 in Eugene, Oregon, the group (nationalforestadvocates.org) says it has about 10,000 members; it publishes a quarterly called Forest Magazine and pays its director Andy Stahl over $91K annually. The organization receives a substantial part of its support from a governmental unit and/or the general public.

FireRescue1 reported that FSEEE claims wildfire retardant drops are expensive, ineffective, and a growing source of pollution for rivers and streams. “There’s no scientific evidence that it makes any difference in wildfire outcomes,” said Andy Stahl. “This is like dumping cash out of airplanes, except that it’s toxic and you can’t buy anything with it because it doesn’t work.”

The case has been followed closely by officials in California, where an extremely wet winter is likely to stoke the growth of early-season light fuels. “This is going to destroy towns and many communities in California, if they allow this to go through,” said Paradise Mayor Greg Bolin, whose town was razed by the Camp Fire five years ago. “To maybe save a few fish, really?”

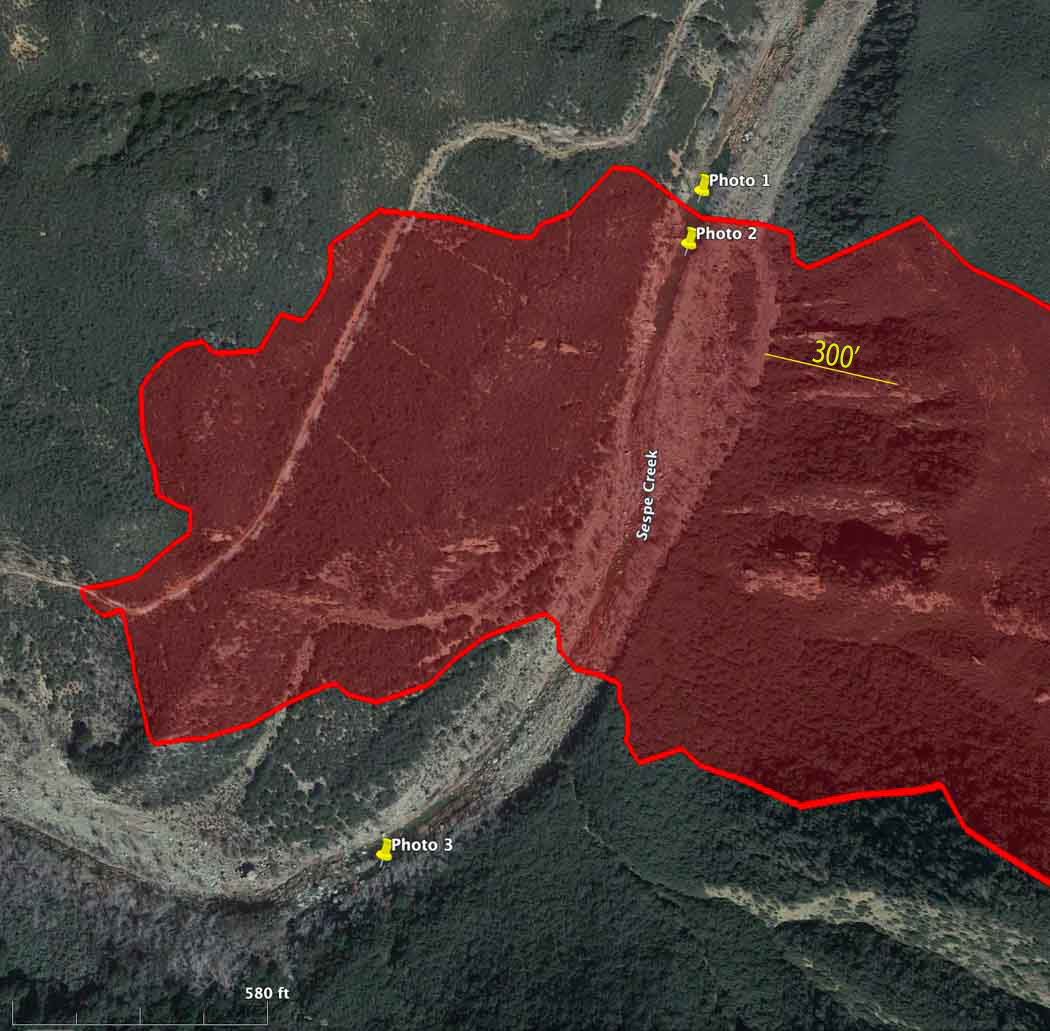

The Smokey Wire is a Forest Service and public lands policy blog administered by Sharon Friedman, Ph.D., forest geneticist, Forest Service retiree, and former Chair of both the Forest Policy Committee and Forest Science and Technology Board at the Society of American Foresters. In a recent post about this retardant case, she commented on a piece in the San Joaquin Valley Sun published about a month ago in April, which noted that if the court sided with FSEEE, the USFS would have to obtain a special permit under the Clean Water Act to use retardant from aircraft — a lengthy process that would span multiple years. During the lawsuit, the USFS initiated the process of receiving such a permit from the EPA with the current 300-foot buffer zone for retardant drops from affected waterways.

In response, FSEEE argued that 300 feet was an arbitrary number. Despite its argument that the USFS had originally created the 300-foot buffer proposal out of thin air, FSEEE then asked the Court for a 600-foot buffer zone.

Judge Christensen noted then that a ruling was pending, because fire season in the West is pending. He expressed skepticism at the nationwide impact of siding with FSEEE and rejected its push for an extended buffer zone. “The last thing I want to do is start imposing magic numbers in terms of buffer zones,” he said. “I mean, that’s way out of my wheelhouse. But I don’t know what the Forest Service did to come up with a 300-feet buffer, and you’re describing it as being essentially nothing. It’s a magic number. And I will tell you, if this Court imposes a 600-foot buffer, that is truly a magic number. So that’s probably not going to happen.”

USFS attorney Alan Greenberg said the Forest Service uses retardant on about 5 percent of wildfires — and less than 1 percent of those drops end up in contact with water.

Christensen said that stopping the use of retardant could result in greater harm from wildfires — including to human life and property and to the environment. (Note that his ruling was not nationwide — it’s limited to the 10 western states where FSEEE alleged harm from pollution into waterways.)

In the lawsuit (online HERE), FSEEE specifies that “the chemical retardants used by wildland firefighting agencies are tested and approved by the United States Department of Agriculture’s Missoula Technology and Development Center, located in this Division. The Forest Service also has a Fire Sciences Lab and Smokejumper Base in this Division. Plaintiff has members who reside in this Division, and who have been injured by the Forest Service actions and activities complained of in this Complaint. Moreover, the Forest Service has discharged aerial fire retardant into navigable waters in this Division without a National Pollution Discharge Elimination System (NPDES) permit.”

After the lawsuit was filed the Forest Service applied to the EPA for a permit that would allow it to continue using retardant without breaking the law. That process could take years. Christensen ordered federal officials to report every six months on their progress; no word yet on whether the USFS will still pursue that EPA permit or whether they have to continue reporting to Christensen about it.

Photo Credit: Josh Stotler

Health risks to firefighters or other people who come into contact with fire retardant are considered low, according to a 2021 risk assessment. But the chemicals can be harmful to some fish, frogs, crustaceans, and other aquatic species. One government study found misapplied retardant could adversely affect dozens of species including crawfish, spotted owls, and threatened fish such as shiners and suckers. To prevent risk, officials and pilots have avoided drops within 300 feet (92 meters) of waterways. Retardant may be applied inside those zones only when if life or public safety is threatened. Of 213 documented instances of fire retardant contacting water between 2012 and 2019, 190 were accidental and the remainder were necessary to protect lives or property, officials said.